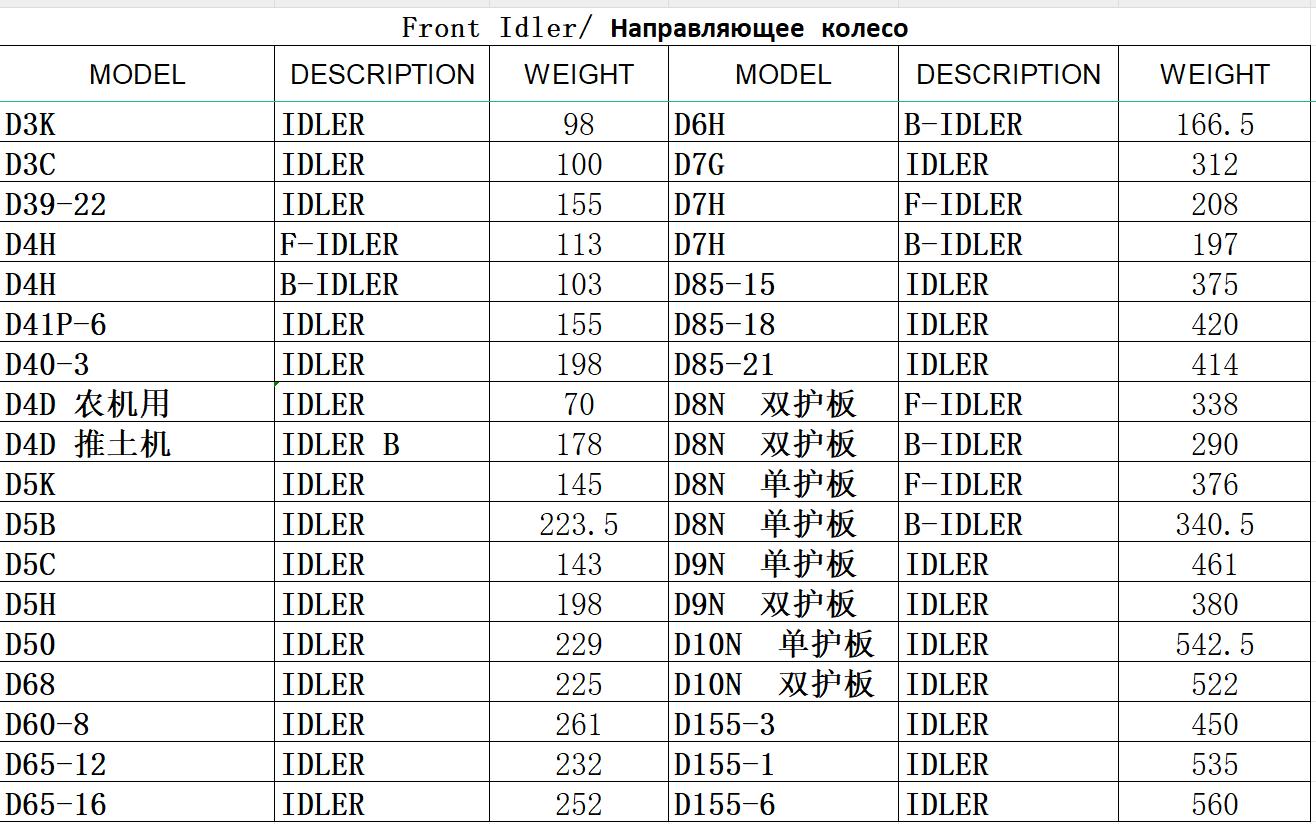

Bulldozer parts/undercarriage /idler assy/ Track Idler /Front Idler Gear/bulldozer Idler/Idler group 14X-30-00114 FOR KOMATSU Dozer D85ESS-2,D65-15,D65EX,D65-12

Undercarriage Parts Idler Group

What is an idler?

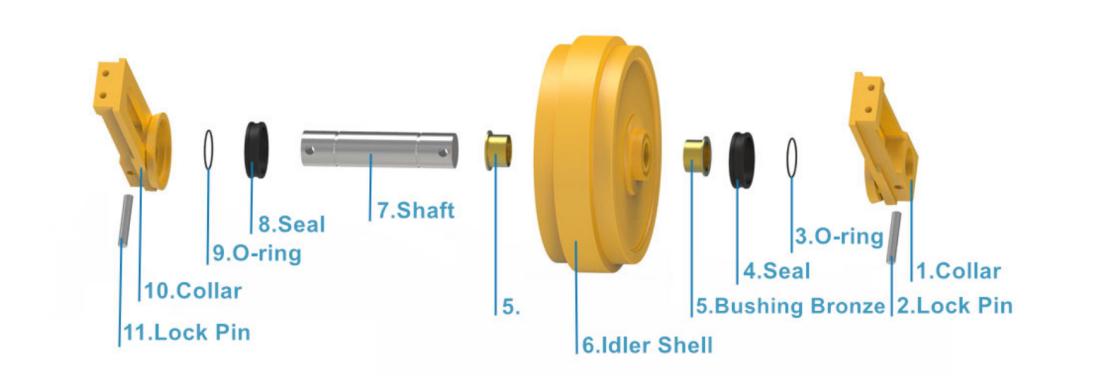

Front idler, which is also called idler group, idler assy or idler wheel, is one part of undercarriage parts for crawler heavy equipments such as excavator, bulldozer, crane, drilling machine it is consist of idler shell, shaft, brackets, Bi-metallic Bearings and seal group. It is made by casting or forging, machining, heat treatment, assembly, painting etc.

The idler is made of idler shell shaft, O-ring, bi-metallic bushing bronze and seal group. It is made by casting or forging, machining, heat treatment, assembly, painting etc. The Idlers are used to guide the track to correct rotation to prevent deviation and derailment.

Idler Structure

01-IDLER SHELL 02-BUSHING BRONZE 03-COLLAR 04-SEAL

05-LOCK PIN 06-O-RING 07-PLUG 08-SHAFT

APPLICATION TYPES

Compatible Brands

Quality of products

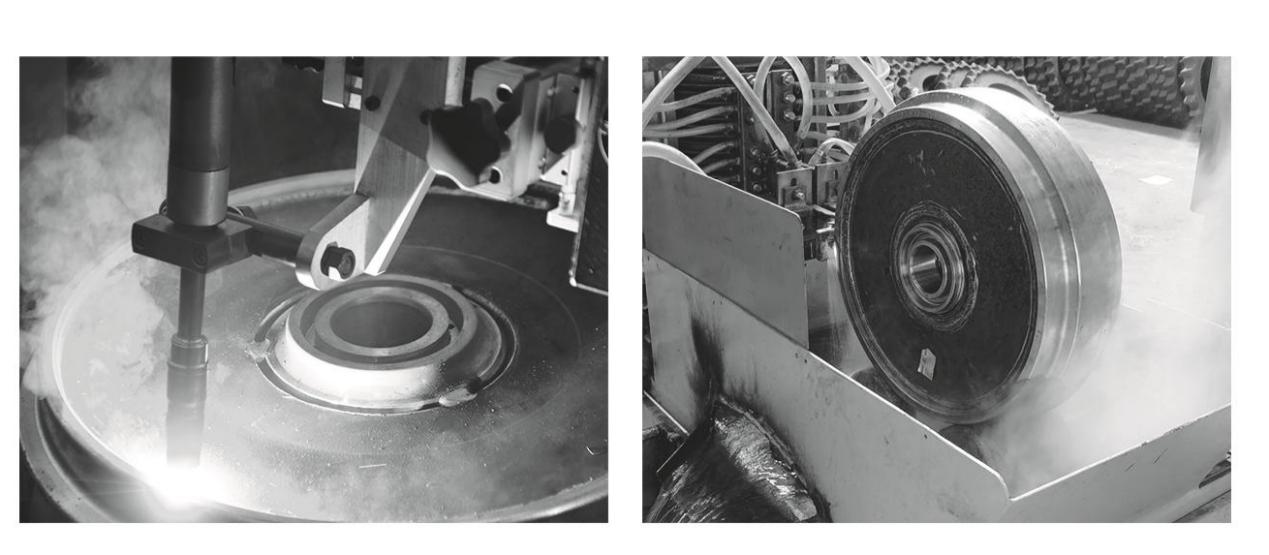

Through quench-tempering processes to ensure excellent mechanical properties, high strength and superior wear resistance to avoid bending and breakage.

Our Idler shell is made of high quality alloy steel 40Mn, through the whole heating quenching and tempering to increase the service life of idler.

Shaft uses high-quality manganese steel, quenched and tempered, high-frequency processing to meet the needs of high-intensity operations.

Production Processes

Our Services

Free technical inquiries and logistic guidance with our experts.

Free repair or replace service during warranty period.

Free special services for all key construction projects.

Company

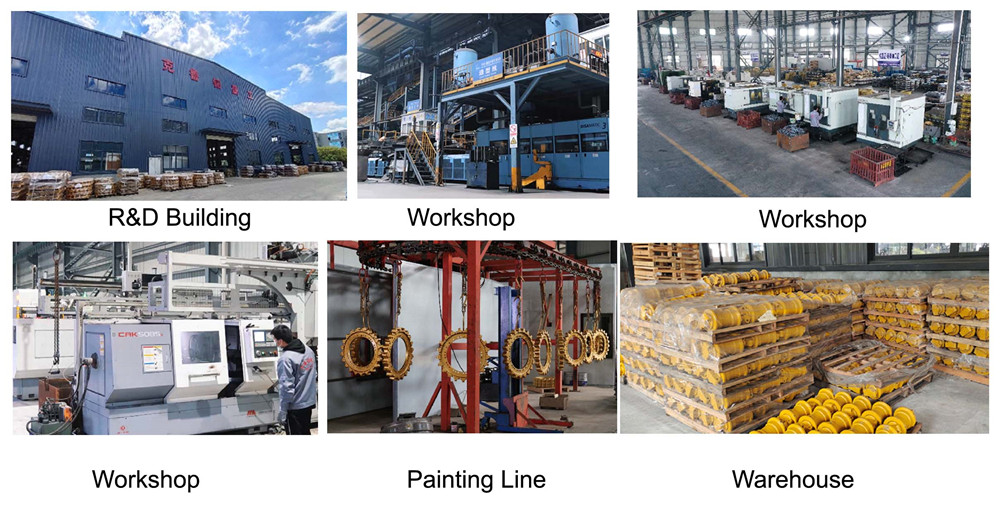

We are a professional of excavator and excavator undercarriage parts manufacturer in China, we can provide standardized products, also can provide customized products, to meet your various needs, create win-win cooperation

Our Factory View

Our Inspection

Our Packing