VOLVO V210/V360/V480/ FORGING BUCKET TEETH/FORGED BUCKET TEETH /GROUND ENGAGING TOOLS/Mining machine parts

PRODUCT DETAIL

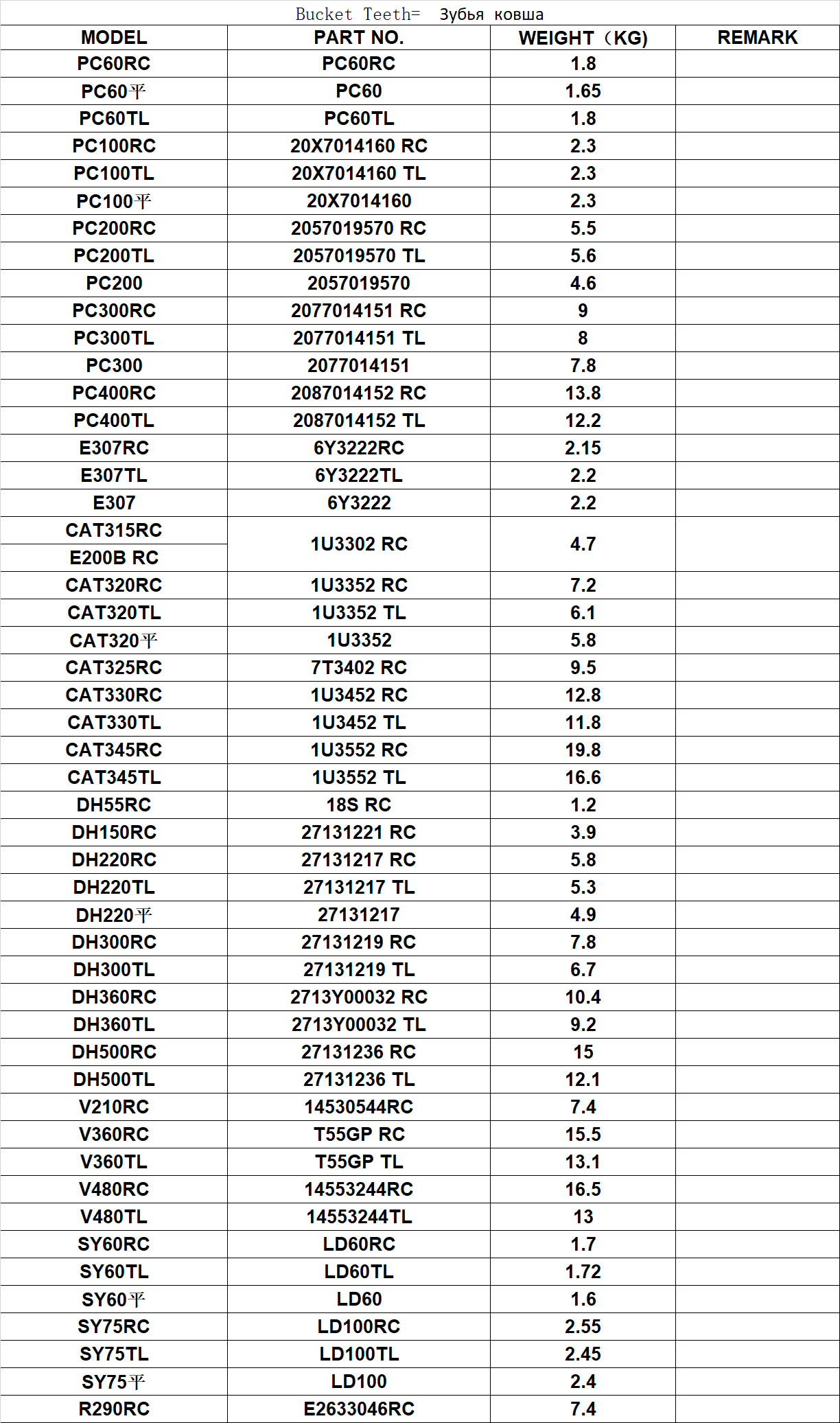

AVAILABLE PRODUCT MODELS

Quality of products

Through quench-tempering processes to ensure excellent mechanical properties, high strength and superior wear resistance to avoid bending and breakage.

Shaft uses high-quality manganese steel, quenched and tempered, high-frequency processing to meet the needs of high-intensity operations.

Every model should be controlled by quality control plan.

All process should be followed by working standard.

All models should be inspected by inspection check sheets.

Compatible Brands

Our Services

Factory sale directly with reasonable price

Flexible payment terms including T/T, D/P and so on

Fast delivery within 30 days after contract established

Professional sales team,quality inspection and report,maritime logistics guidance

Free technical inquiries and logistic guidance with our experts.

Free repair or replace service during warranty period.

FAQ

1.Are you manufacturer or trading company?

We are a manufacturer, we have our own factory and production lines to provide competitive products with high quality and good price.

2.Can your factory print our logo on the products?

Yes, we can laser print customer's logo on the product with the permission from customers for free.

3.Is your factory able to design our own package and help us in market planning?

We willing to help our customers to design their package box with their own logo. We have a design team and a marketing plan design Team to service our customers for this.

4.Can you accept trail/small order?

Yes, in the beginning we could accept small quantity, to help you open your market step by step.

If you have any other questions, please do not hesitate to contact us!

COMPANY

We are a professional of excavator and excavator undercarriage parts manufacturer in China, we can provide standardized products, also can provide customized products, to meet your various needs, create win-win cooperation.

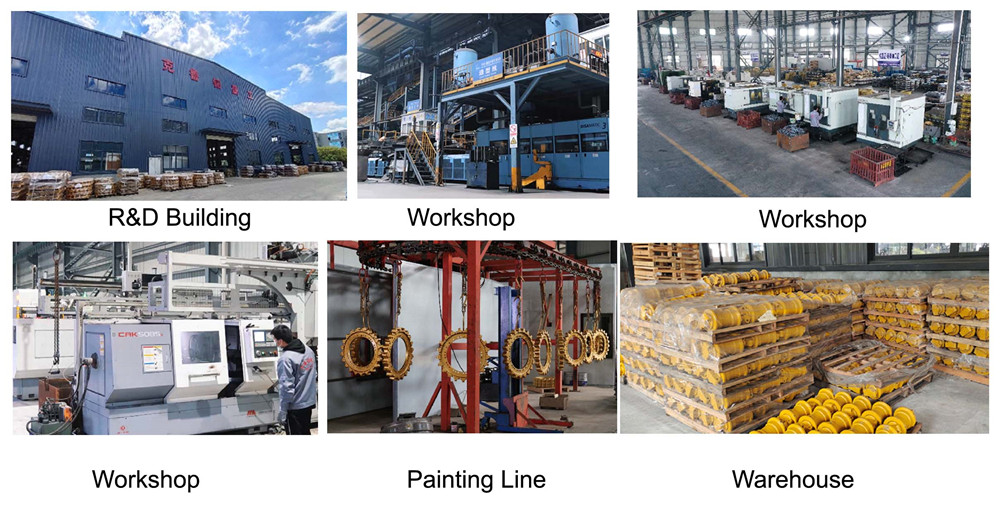

Our Factory View

Our Inspection