Excavator bottom rollers leak oil, supporting sprocket is broken, walking is weak, walking is stuck, track tightness is inconsistent and other faults, and these are all related to the maintenance of the excavator undercarriage parts!

Track Bottom Roller

Avoid Soaking

During the work, try to avoid the Track Roller soaked in muddy water for a long time. After the daily work is completed, the crawler on one side should be propped up, and the travel motor should be driven to shake off the dirt, gravel and other sundries on the crawler.

keep dry

During construction in winter, the track rollers must be kept dry. Because there is a floating seal between the outer wheel and the shaft of the bottom roller, if there is water, it will freeze at night. When the excavator is moved during the next day's work, the seal will be scratched when it comes into contact with the ice, resulting in oil leakage.

Avoid Damage

Damage to the track roller will cause many failures, such as the track group walking deviation, walking weakness, etc.

Carrier Roller

Avoid Damage

The supporting carrier roller is located above the X frame, and its function is to maintain the linear motion of the chain track. If the support carrier roller is damaged, the track chain track cannot keep straight.

keep it clean and not soak in muddy water

The carrier roller is a one-time injection of lubricating oil. If there is oil leakage, it can only be replaced with a new one. During work, try to avoid the bottom roller from being soaked in muddy water for a long time. Keep the inclined platform of the X frame clean at ordinary times. Excessive accumulation of dirt and gravel hinders the rotation of the carrier roller.

Idler Assy

The Idler is located in front of the X frame,keep the direction ahead.

Keep the idler in front during operation and walking, so as to avoid abnormal wear of the chain rail, and track adjuster assy can also absorb the impact brought by the road surface during work to reduce wear.

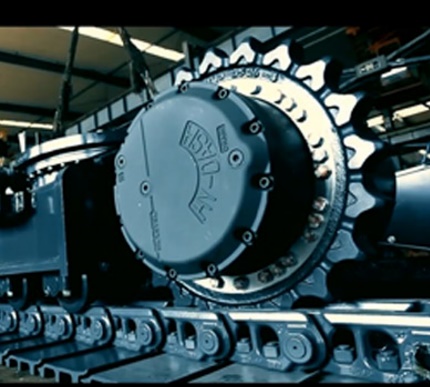

Sprocket/Excavator Rim

Keep the sprocket behind the X frame

The sprocket is located at the rear of the X-frame, because it is fixed directly on the X-frame without shock absorption, If the drive wheel travels in front, it will not only cause abnormal wear to the rim and chain rail, but also have a bad effect on the X frame, and the X frame may have problems such as early cracking.

Clean the guards regularly

The travel motor guard plate can protect the motor, and at the same time, some mud and gravel will enter the internal space, which will wear the oil pipe of the travel motor, and the moisture in the mud will corrode the joint of the oil pipe, so the guard plate should be opened regularly Clean out the dirt inside.

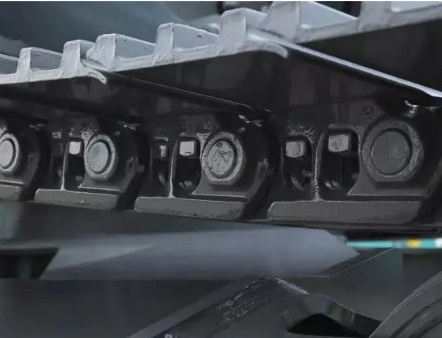

Track Group

The track group is mainly composed of track shoes and chain. The track shoes are divided into standard plates and extended plates. The standard plate is used for earthworks and the extended plate is used for wet conditions.

Clean up gravel

Working in a mine environmen, Worst wear on track shoes. Gravel sometimes gets stuck in the gap between two boards when working, When it comes into contact with the ground, it will produce impact pressure on the two plates. Track shoes are prone to bending and deformation, and long-term working will also cause cracking problems at the bolts of the track shoes.

Avoid excessive track tension

The chain link is in contact with the driving ring gear and is driven by the ring gear to rotate. Excessive track group tension will cause early wear of the chain link, sprocket and idler.

Post time: Apr-11-2023