HYUNDAI R55-5DF/R60/R80/R130/R200/R220/R305/R455 Track Roller & Bottom Roller/Under carriage parts/excavator parts/down roller

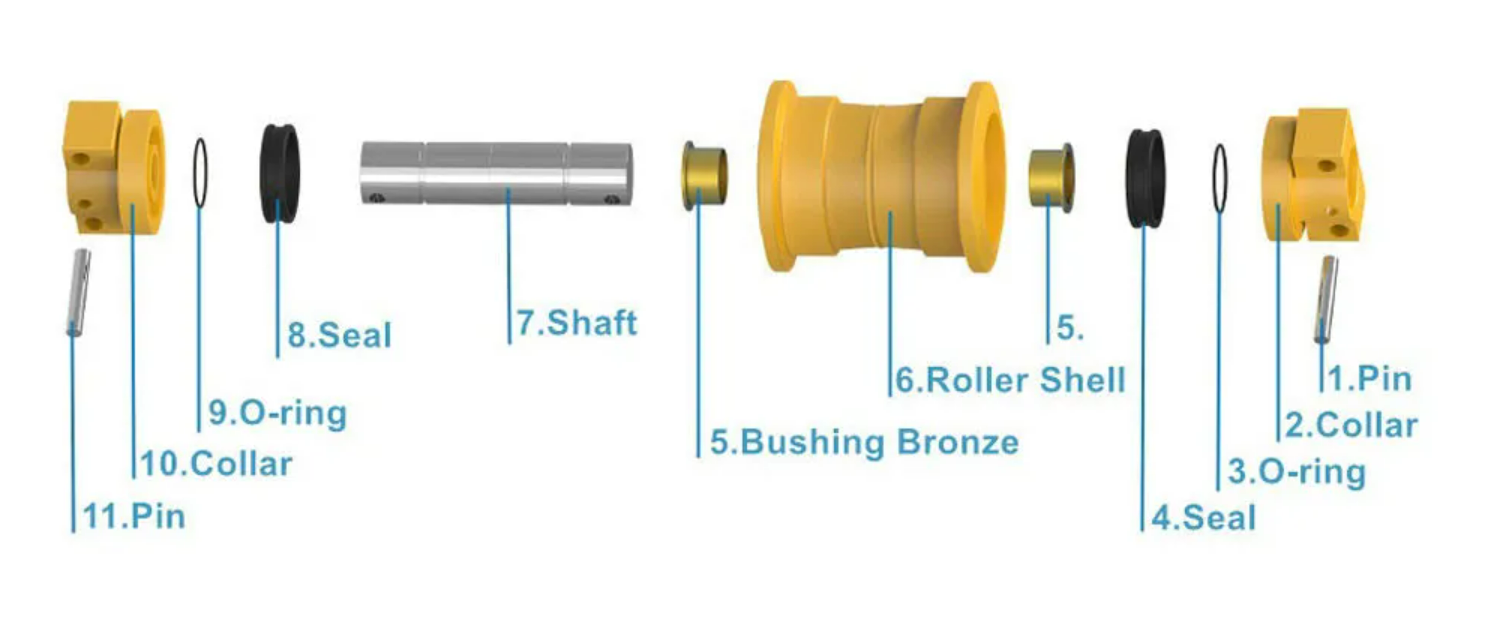

Undercarriage Parts Track Roller & Bottom Roller

Track Link Description

Wheel body: forged from 50Mn round steel with good hardenability: The heat treatment process of quenching and tempering and medium frequency surface quenching ensures its strength and wear resistance.

Shaft: 45 # round steel material, heat treatment process of quenching and tempering + medium frequency surface quenching, surface hardnes:HRC52-60. depth of hardened layer 3-6mm, excellent comprehensive performance.

Floating oil seal: made of high chromium and high molybdenum alloy.

Hardness HRC65-72 working surface roughness 0.1uM-0.2uM

O-ring: It is produced from butylene and acrylonitrile, which are copolymerized into butylene and acrylonitrile, and has better oil resistance and high temperature resistance.

MODER

Quality of products

Through quench-tempering processes to ensure excellent mechanical properties, high strength and superior wear resistance to avoid bending and breakage.

Our roller shell is made of high quality alloy steel, through the whole heating quenching and tempering to increase the service life of supporting wheels.

Shaft uses high-quality manganese steel, quenched and tempered, high-frequency processing to meet the needs of high-intensity operations.

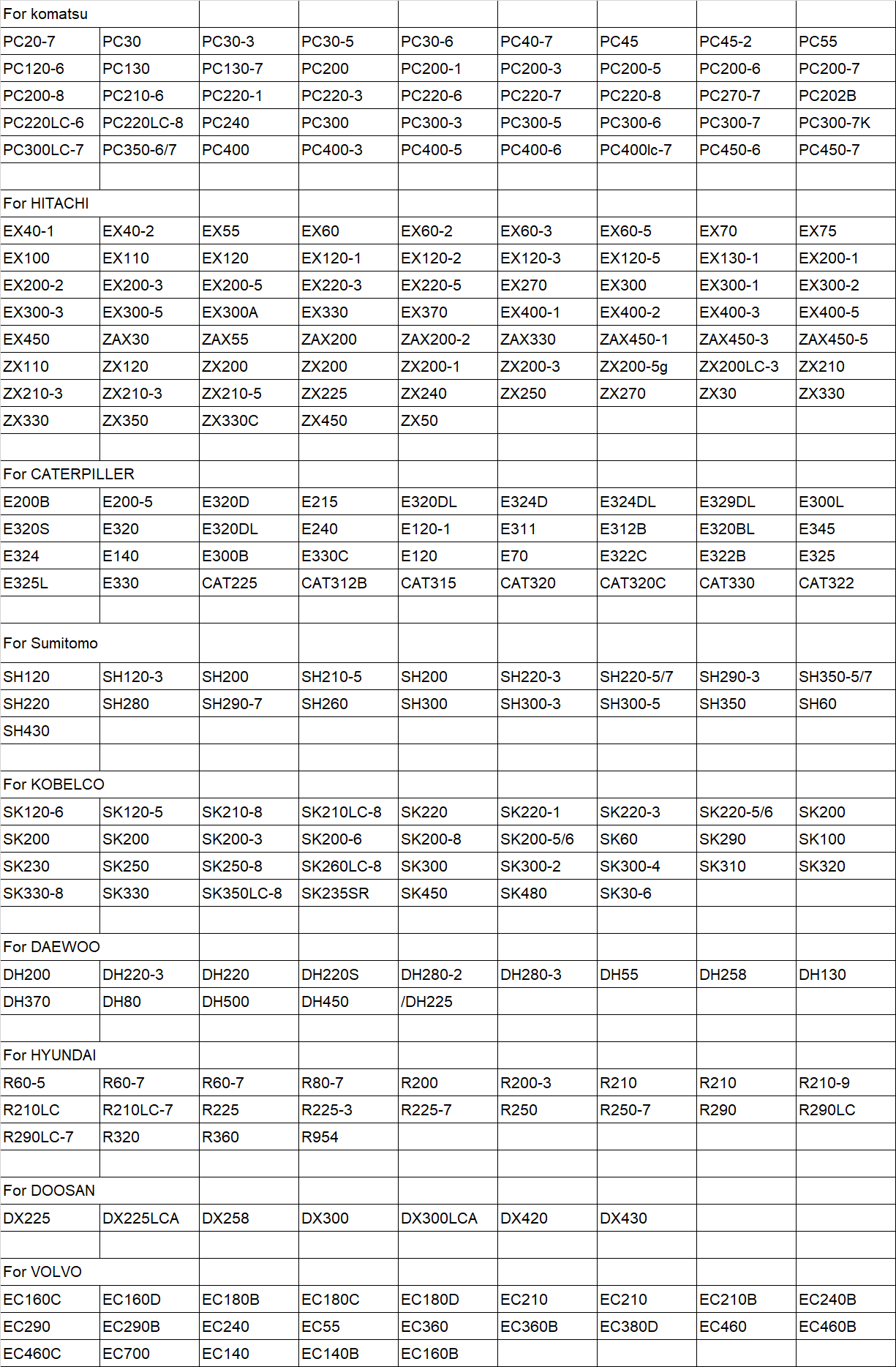

Compatible Brands

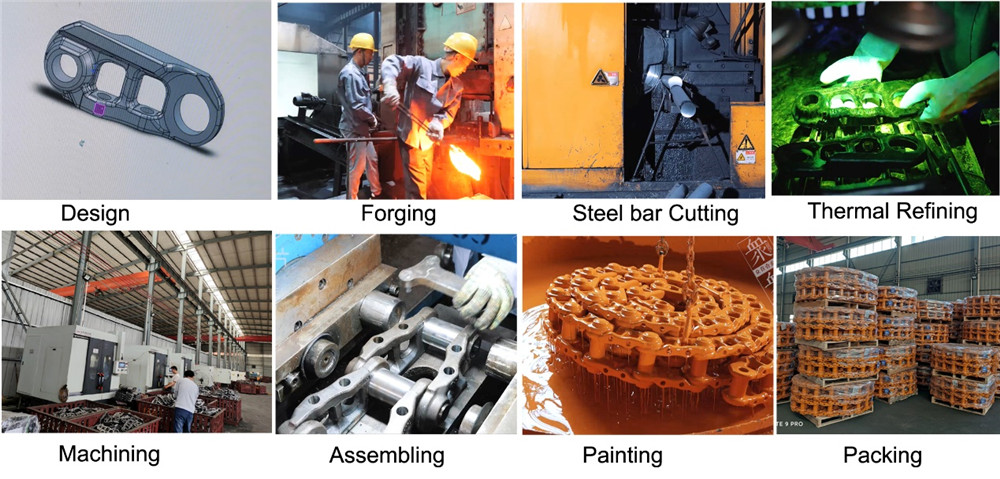

Production Processes

Our Services

Factory sale directly with reasonable price

Flexible payment terms including T/T, D/P and so on

Fast delivery within 30 days after contract established

Professional sales team,quality inspection and report,maritime logistics guidance

Free technical inquiries and logistic guidance with our experts.

Free repair or replace service during warranty period.

Free special services for all key construction projects.

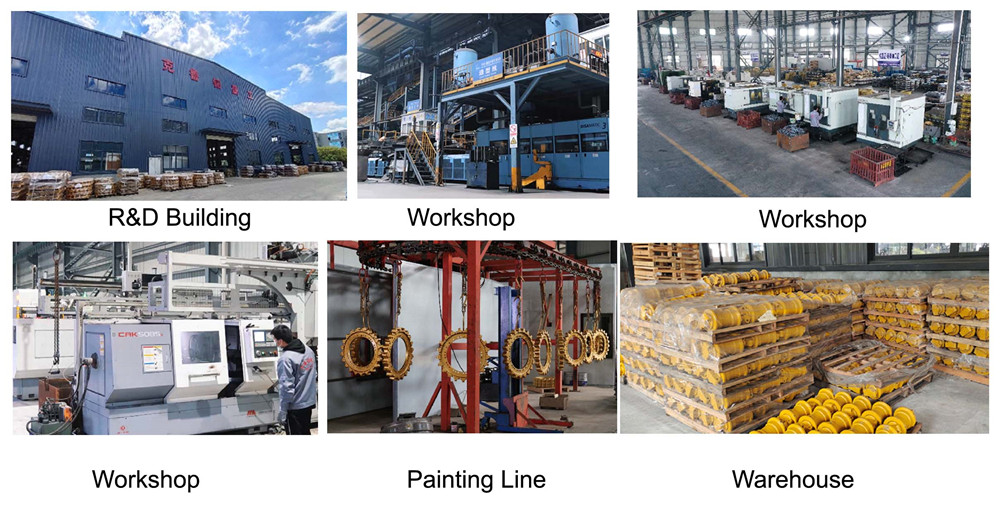

Company

We are a professional of excavator and excavator undercarriage parts manufacturer in China, we can provide standardized products, also can provide customized products, to meet your various needs, create win-win cooperation

Our Factory View

Our Inspection

Our Packing